Very Low Hours [2220 Hours]. The machine is in perfect working order and is available by Private treaty sale due to reinvestment in new machinery.

MODEL: DMG NLX 2500/700 SY

YEAR: 2019

HOURS: 2220

CONDITION: Excellent

AVAILABILITY: Immediate

Full Specifications

Control

- M730UM CELOS With MAPPS V.

- ERGOline operation panel with 21.5-inch multi-touch screen

- 2 Keys

Capacity

- Swing over Bed mm(in.) - 920 (36.22) <interfere with front cover: 620 (24.41)>

- Swing over Cross Slide mm (in.) - 740 (29.13)

- Maximum Distance Between Spindle Nose Surfaces mm (in.) - 961 (37.83)

- Max. Turning Diameter mm (in.) - 366 (14.41)°4, 356 (14.02)"5 [406 (15.98) <12st VDI high-precision quick-change turret (DIN)>] [348 (13.7) <16st turret head>] [278 (10.95) <20st turret head>]

- Standard Turning Diameter mm (in.) - 271 (10.67)"4 275 (10.83)5[330 (12.99), 335 (1319) <10st turret head>] [260 (10.24) <12st VDI high-precisionquick-change turret (DIN)>] [206 (8.11) <16st turret head>] [192 (7.56) <20st turret head>]

- Max. Turning Length mm (in.) - 705 (27.76)

- Bar Work Capacity mm (in.) - 80 (3.15) [90 (3.54) <continuous through spindle hole diameter 91 (3.58)>] [102 (4.02) <continuous through spindle hole diameter 103 (4.06)>]

Travel

- X-Axis Travel mm (in.) - 260 (10 24)

- Y-Axis Travel mm (in.) - ‡50 (‡1.97)

- Z-Axis Travel mm (in.) - 795 (31.30)

- Spindle 2B-Axis Travel mm (in.) - 734 (28.90)

Spindle 1

- Kitagawa 10 inch Hollow Chuck BB210A821 - 3 Jaw Hydraulic Chuck

- Through Hole Diameter 81mm - Max. Spindle Speed min-1 - 4000 <through spindle hole diameter 111 mm (4.37 in.)>]

- Number of Spindle Speed Ranges Step - 2 <winding changeover>

- Spindle Nose Type - JIS A2-8

- Through Spindle Hole Diameter mm (in.) - 91 (3.58) [111 (4.37)]

- Spindle Bearing Inner Diameter mm (in.) - 140 (5.51) [160 (6.30) <through spindle hole diameter 111 (4.37)>]

- Chuck - 10" solid & hollow [12" hollow <through spindle hole diameter 111 mm (4.37 in.)>]

- Minimum Spindle Indexing Angle ° - 0.001

Spindle 2

- Kitagawa 6 inch Hollow Chuck B206A521F - 3 Jaw Hydraulic Chuck - Through Hole Diameter 45mm

- Max. Spindle Speed min-1 - 6000 [5000 <through spindle hole diameter 73 mm (2.87 in.)>]

- Number of Spindle Speed Ranges Step -1

- Spindle Nose Type - JIS A2-5 [JIS A2-6 <through spindle hole diameter 73 mm (2.87 in.)>]

- Through Spindle Hole Diameter mm (in.) - 43 (1.69) [73 (2.87)]

- Spindle Bearing Inner Diameter mm (in.) - 85 (3.35) [120 (4.72) <through spindle hole diameter 73 (2.87)>]

- Chuck - 6" solid & hollow [8" hollow <through spindle hole diameter 73 mm (2.87 in.)>]

- Minimum Spindle Indexing Angle ° - 0.001

Turret

- Turret Type

- Rotary Tool Spindle for the 20 Station in-house bolt tightened turret,

- BMT (Built-in Motor Turret)

- Rotary Tool Machining ability:

- Rotary Tool Spindle, 10,000rpm

- Drill 20mm Diam eter, Tap M16

- Number of Tools on Turret Tools - 20

- Shank Height for Square Tool mm (in.) - 25 (1) [20 (3/4) <12st VI high-precision quick-change turret (DIN), 16st turret head, 20st turret head>]

- Shank Diameter for Boring Bar"3 mm (in.) - 50 (2) <subspindle side 32 (1-1/4)> [32 (1-1/ 4)1*3 [40 (1.57) <12st VDI high-precision quick-change turret (DIN)>] [25 (1) <16st turret head>] [32 (1-1/4) <20st turret head>]

Feedrates

- Rapid Traverse Rate mm/min (ipm) - X. Z. B: 30000 (1181.10), Y: 10000 (393.70)

- Jog Feedrate mm/min (ipm) - ×z.Y.B:0-5000 (196.85)

Motors

- Spindle 1 Drive Motor (25% ED/ 50%ED /Cont.) kW (HP) - 18.5/18.5/15 (24.7/24.7/20) (26/26/22 (34.7/34.7/30) (10 min/30 min/cont <high output> [(22/18.5 (30/24.7) (30 min/cont.) <Through Spindle hole diameter 111 mm (4.37 in.)>]

- Spindle 2 Drive Motor (25% ED/Cont.) kW (HP) - 11/7.5 (15/10)

- Rotary Tool 1 Spindle Drive Motor (3min / 5 min /Cont. kW (HP) - 5.5/4.9/4.2 (7.5/6.5/5.6) (25%ED/30%ED,cont.) <12st bolt-tightened turret [5.5/5.5/3.7 (7.5/7.5/5) (3 min/5 min/cont.) <10st bolt-tightened turret, 16st VDI quick-change turret, 20st bolt-tightened turret>] [10.7/8.5/6.1 (14.3/11.3/8.1) (15%ED/30%EDcont.) <12st VI high-precision quick-change turret (DIN)>]

- Feed Motors kW (HP) - X. Y. Z: 3.0 (4.0), B: 2.0 (2.7)

- Hydraulic Pump Motor kW (HP) - 2.2 (3)

- Lubricating Pump Motor kW (HP) - 0.02 (0.027)

- Coolant Pump Motor kW (HP) - 0.55 (0.73)0.35 (0.46)

- Cooling Oil Pump Motor kW (HP) - 1.43 (1.9)

- Required Air Sources

- Compressed Air Supply MPa (psi). L/min (gpm) - 0.5 (72.5). 150 (39.6) <ANR>

Tank Capacity

- Hydraulic Oil Tank Capacity L (gal.) - 10 (2.64)

- Lubricating Oil Tank Capacity L (gal.) - 4.2 (1.1)

- Coolant Tank Capacity L (gal.) - 366 (96.62)

- Oil Chiller Tank Capacity L (gal.) - 10 (2.64)

Coolant Supply/Chip Removal

- High-Pressure Coolant System (800/1, 100 W)

- Max. pump pressure: 0.8 MPa (116 psi)

- Chip Conveyor (Right Discharge, Hinge Type)

Additional Options Included

- Manual in Machine Tool Presetter (Pivoting Type)

- Signal Light

- Work Pice Unloader

- Bar Feed Interface

- Mist Collector interface

- Swarf Bin

Control Options Included

- DXF Import Function

- Islands

- Open Pocket

- High Speed Canned Cycle

- Block Skip

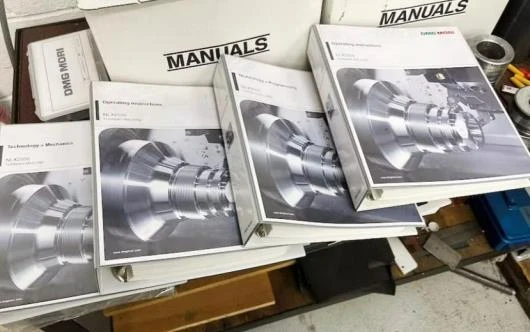

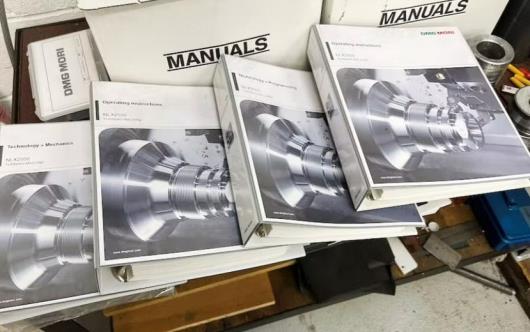

Tooling Package. Includes Driven and Static Holders.

Tooling in the Turret and on the Pallet is included, (Please note no cutting tools are included)

1 x MNZ0092000. SINGLE RADIAL STATIC TOOL 20mm

4 x MNZ0112000. DOUBLE RADIAL STATIC TOOL 20mm

2 x MNZ0122000. RADIAL REVERSIBLE DOUBLE SIDE TWIN STATIC TOOL 920mm

4 x MNZ0470132 AXIAL DRIVEN TOOL I=1:1 ER32 12000 RPM EXT. COOLANT

3 x MNZ0440125. RADIAL DRIVEN TOOL ER25 |=1:1 12000 RPM EXT. COOLANT

1 x MNZ0440132. RADIAL DRIVEN TOOL ER32 12000 RPM

1 x MNZ0530132L. PORTAUT. RADIALE LAMA DA 32 LUB. I+E

6 x MNZ0143200. SINGLE AXIAL BORING BAR HOLDER 032 INT. 100mm I+E COOLANT

5 x KIT1000001 PLUG KIT FOR BORING BAR HOLDER

1 x MNZO144000 BORING BAR HOLDER 940 H100 EXT.+ INT. COOLANT

1 x KIT1000018 PLUG KIT FOR BORING BAR HOLDER2 x 32mm SINGLE AXIAL BORING BAR HOLDE

1 x 25mm DOUBLE OFFSET BORING BAR HOLDER.

Plus Some additional Holders.

Additional Driven Tooling may also be available to purchase

Hampton Lovett Industrial Estate

Droitwich

WR9 0QG

UK